Calibrated as per ISO 6507-3, IS 1501 (Part 3) and/or ASTM E92 (Annex A4), ASTM E384

Calibrated at Fmi Calibration Laboratory, NABL accredited (ISO/IEC 17025:2017)

Specially curated high-quality steel, aluminium and brass material

Specially designed heat treatment and cryogenic treatment to achieve maximum long term hardness stability, consistency and repeatability

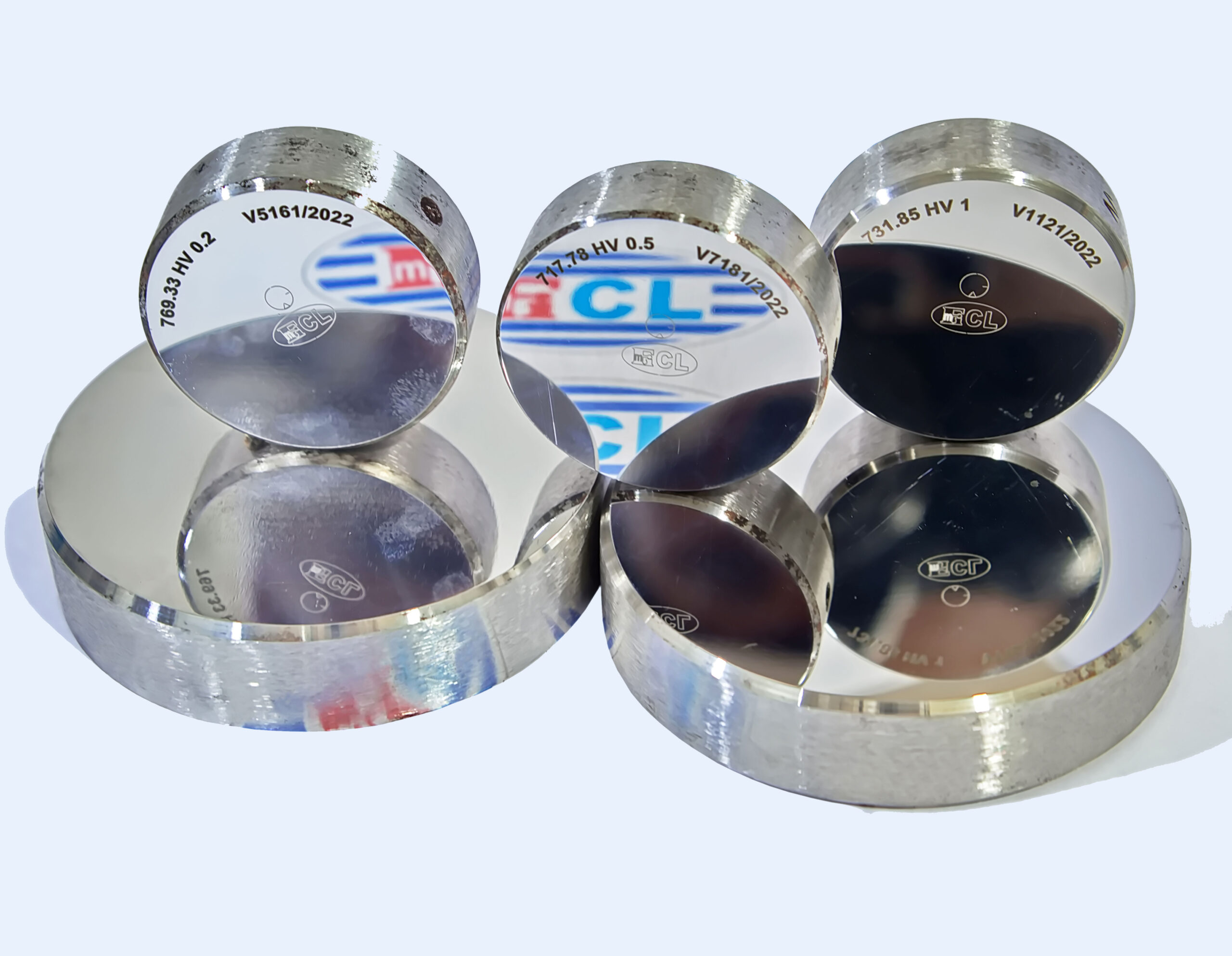

Mirror surface finish by grinding, lapping and diamond polishing

Calibration traceability: Vickers test blocks are calibrated using a standardising hardness testing machine which is directly and indirectly calibrated as per the requirements of ISO 6507-3 and ASTM E92 annex A2; using instruments traceable to SI system of units realised at NPL-India, NPL-UK, IMGC, NIST or PTB either directly or through NABL/UKAS/NVLAP/A2LA/DAkkS accredited laboratories.

LASER marking on the surface of hardness value, Serial number, lab logo and reference indent location.

Available in shapes: Φ36

Recommended key usage: Perform Indirect verification/calibration of hardness testers as per ISO 6507-2, IS 1501 (Part 2) or ASTM E92 annex A1, ASTM E384, periodic quality control checks/intermediate checks, daily verifications, etc.