In the world of material testing, precision defines quality. Whether it’s automotive components, aerospace materials, or engineering alloys, manufacturers must ensure the strength and durability of every part they produce. One of the most trusted methods for evaluating material hardness is the Vickers Hardness Test — and the Vickers Test Block plays a crucial role in ensuring that every hardness test remains reliable and consistent.

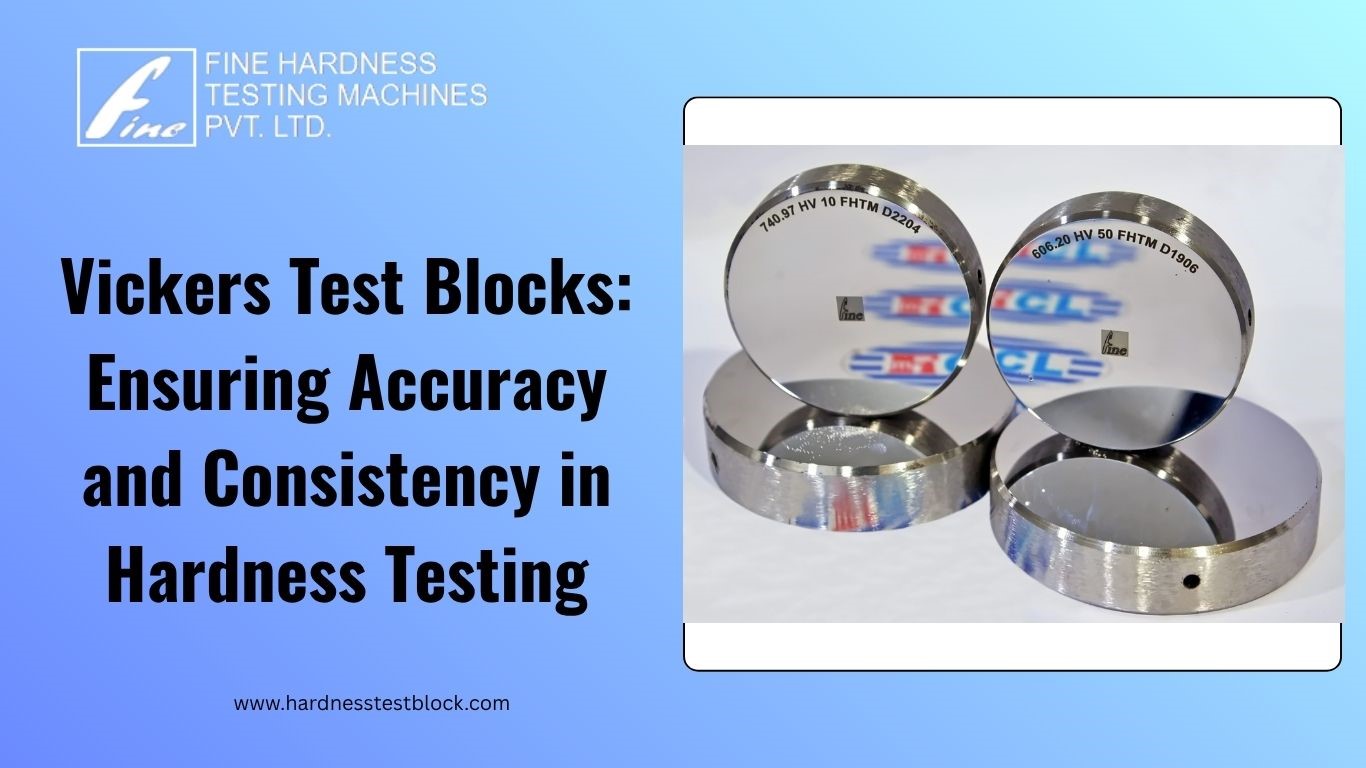

At Hardness Test Block, we manufacture and supply high-quality Vickers Test Blocks that conform to international standards, providing accurate calibration and verification for hardness testing machines used in laboratories and industrial applications.

Understanding the Vickers Hardness Test

What Is a Vickers Test Block?

Each test block is meticulously calibrated against master blocks that are traceable to national and international standards such as ISO 6507 and ASTM E384.

When used properly, these blocks ensure that the hardness testing equipment produces accurate, consistent, and reliable results.

Importance of Vickers Test Blocks

Key reasons why industries rely on Vickers Test Blocks:

Type of Vickers Test Blocks

At Hardness Test Block, we supply a complete range of Vickers Test Blocks suitable for various loads and applications.

Applications of Vickers Test Blocks

Vickers Test Blocks are used across a wide range of industries and testing environments, including:

- •Calibration Laboratories

- •Automotive Component Manufacturing

- •Aerospace & Defense Materials Testing

- •Research & Development Laboratories

- •Metallurgical Quality Control Departments

- •Tool & Die Manufacturing

By verifying the hardness tester with a standard block, manufacturers ensure every component they produce meets global quality expectations.

Features of Vickers Test Blocks from Hardness Test Block

At Hardness Test Block, we combine technical expertise and high-precision manufacturing to produce test blocks that meet the most stringent requirements.

Here’s what sets our products apart:

- •High Surface Finish: Achieved through advanced polishing and finishing techniques.

- •Traceable Certification: All blocks come with calibration certificates traceable to NABL/ISO standards.

- •Durable Construction: Made from stabilized steel for long-term performance.

- •Wide Hardness Range: Covers low, medium and high hardness values.

- •Precision Manufacturing: Tight tolerances ensure accuracy in every measurement.

- •Custom Orders:Blocks can be made to specific loads or materials upon request.

Every test block is designed to ensure maximum stability and reproducibility for critical hardness verification tasks.

Why Choose Hardness Test Block for Vickers Test Blocks?

Choosing the right supplier is as important as the equipment itself. Hardness Test Block has built a strong reputation for manufacturing and supplying reliable, certified, and high-precision hardness reference blocks.

Our Competitive Advantages:

- •ISO-Certified Calibration Standards

- •Experienced Technical Team

- •Prompt Delivery and Global Shipping

- •Affordable Pricing

- •Comprehensive After-Sales Support

We are committed to supporting industries with products that uphold testing accuracy, standard compliance, and quality assurance.

Benefits of Regular Calibration Using Vickers Test Blocks

Regular calibration using Vickers Test Blocks ensures your hardness testing equipment continues to perform reliably.

Some key benefits include:

- •Enhanced Reliability: Ensures every hardness measurement meets exact standards.

- •Cost Efficiency: Prevents costly production errors due to incorrect readings.

- •Audit Compliance: Helps pass third-party audits and certifications.

- •Operational Efficiency: Minimizes downtime caused by inaccurate results.

- •Consistent Product Quality: Supports uniform material performance across batches.

In industries where precision determines safety and performance, periodic verification using Vickers Test Blocks is indispensable.

Conclusion

At Hardness Test Block, we are dedicated to supplying certified, high-quality Vickers Test Blocks that help industries maintain testing excellence and quality assurance.

Whether you are in automotive, aerospace, metallurgy, or R&D, our Vickers Test Blocks are your trusted standard for dependable and traceable hardness testing.