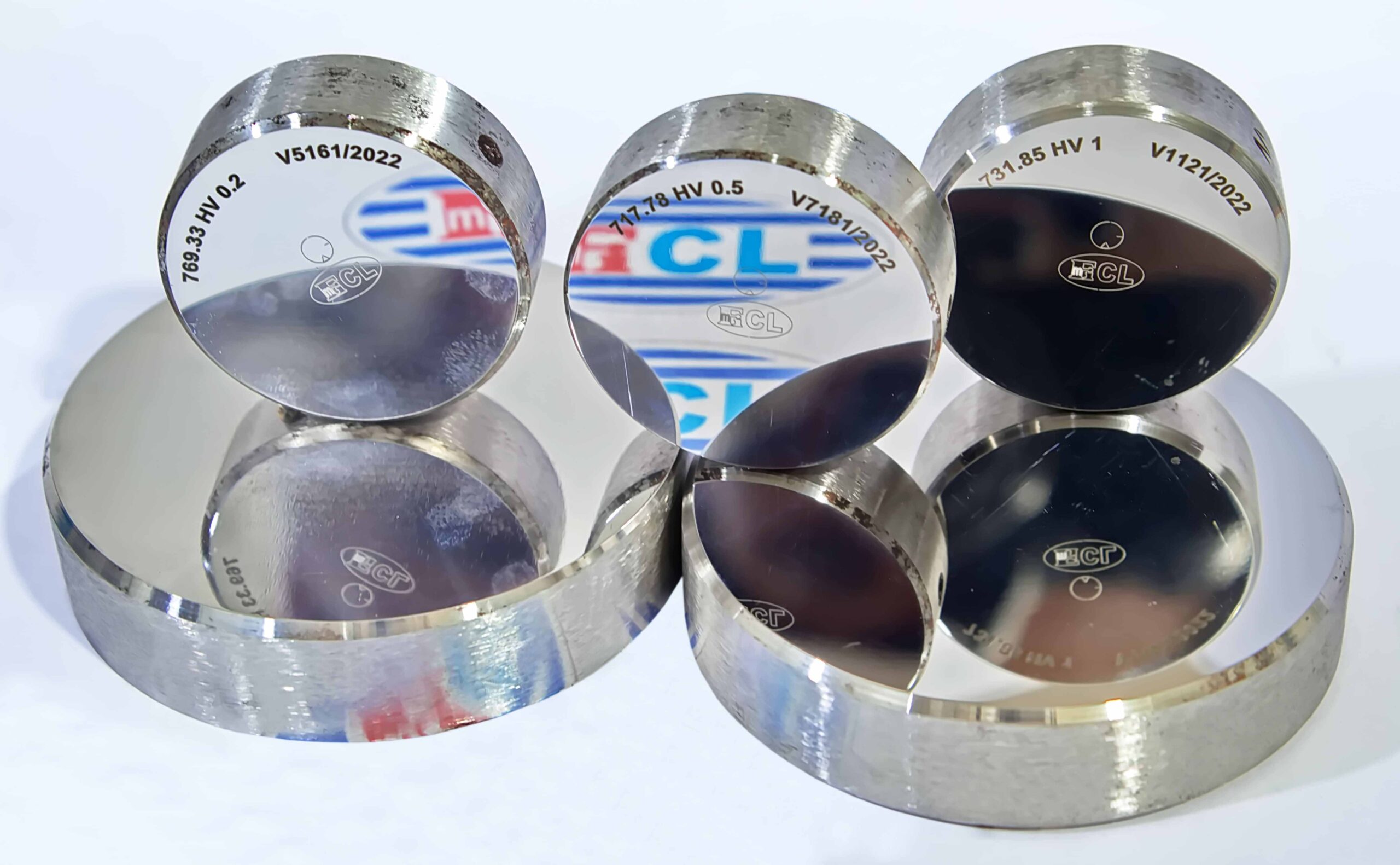

Standard Low load Vickers/Micro-Vickers Test Blocks

Features

- Calibrated as per ISO 6507-3, IS 1501 (Part 3) and/or ASTM E92 (Annex A4), ASTM E384

- Calibrated at Fmi Calibration Laboratory, NABL accredited (ISO/IEC 17025:2017)

- Specially curated high-quality steel, aluminium and brass material

- Specially designed heat treatment and cryogenic treatment to achieve maximum long term hardness stability, consistency and repeatability

- Mirror surface finish by grinding, lapping and diamond polishing

- Calibration traceability: Vickers test blocks are calibrated using a standardising hardness testing machine which is directly and indirectly calibrated as per the requirements of ISO 6507-3 and ASTM E92 annex A2; using instruments traceable to SI system of units realised at NPL-India, NPL-UK, IMGC, NIST or PTB either directly or through NABL/UKAS/NVLAP/A2LA/DAkkS accredited laboratories.

- LASER marking on the surface of hardness value, Serial number, lab logo and reference indent location.

- Available in shapes: Φ36

- Recommended key usage: Perform Indirect verification/calibration of hardness testers as per ISO 6507-2, IS 1501 (Part 2) or ASTM E92 annex A1, ASTM E384, periodic quality control checks/intermediate checks, daily verifications, etc.

Available hardness scales and ranges as below

| Standard Low load / Micro Vickers Test Blocks | ||

| Scale | Hardness Range | Material / Size |

| HV-50 gm | Upto 232 HV | Steel / Dia 36 mm |

| HV-100 gm | Upto 464 HV | |

| HV-200gm, HV-300 gm, HV-500 gm , HV-1 | 80-120, 120-200,200-300,300-400, 400-500,500-600,600-700,700-850 | |